THE LIFETIME PART THAT DOESN’T LAST A LIFETIME

It’s something I see all the time. A client brings their car in because the brakes are squealing. We all hate that sound, and how embarrassing for your quarter million dollar car that creates such amazing engine and exhaust tones to sound like nails on a chalk board when coming to a stop. For some, this car is their daily driver, and ironically, that’s precisely the reason this squeal is happening.

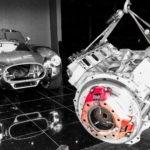

Carbon ceramic brake systems were developed for racecars. They are made using a very strong material that is designed to withstand immense pressure and go through very high temperature heat cycles (getting very hot before cooling off). Naturally they have made their way to the supercar market and are pretty standard nowadays. There’s nothing wrong with that. These cars are designed to hit speeds that push these brakes to the pressures and temperatures they are supposed to reach.

The problem is that a lot of people use a supercar as a putt-around-town daily driver. They drive to work in stop-and-go traffic, cruise on the freeway a bit, and overall drive pretty tamely, not doing nearly enough to get the brakes as hot as they’re meant to. What ends up happening is that these brakes end up going through tons of low-level heat cycles. Over time these heat cycles will actually start changing the chemistry of the carbon ceramic causing it to be more brittle. For the pads, this happens on the surface. A brittle layer forms on the face that presses against the rotor and they start to squeal. Watch THIS VIDEO to learn how to easily get rid of that brittle layer and stop the squeal yourself.

For the rotors, they don’t really wear down very much. They just slowly start to get more and more brittle, losing more and more integrity. The tricky thing is, it’s very hard to distinguish this lost integrity. On traditional rotors, you can just measure the thickness or weigh them to see how good they are. In fact the rotor weight is still the metric used by most dealers to determine if carbon ceramic rotors are still good.

However, the weight loss doesn’t tell the whole story. It doesn’t tell you what’s actually going on inside the rotor material. The correct way is to use a special tool called the Carbotech. This tool sends an electrical current through the rotor. Based on the composition of the rotor, the current will create electromagnetic waves which are interpreted by the Carbotech and given to us a rating. If that number is above the minimum rating for that rotor, then the rotor is still good.

I found only one dealer in Los Angeles who has the Carbotech (who requested to remain nameless), and they were kind enough to let me test a set of carbon ceramic rotors. These rotors were two years old with 2,000 miles on them. They had a composition rating of 61 when new, and a minimum rating of 39. When we tested them, we got a rating of 57.2. That’s a 17.2% loss in just 2,000 miles. If this is a linear progression, we can expect to see these rotors reaching their limits around 10-12,000 miles.

For the average daily driver, 12,000 miles is about one year of driving. It wouldn’t surprise me in the least if we start seeing these rotors start to fail sooner than later.